Coating lines

Coating lines

The painting room is sealed by glass and kept at constant temperature; pre-treatment and after coating drying, dust-proof and insect-proof steel mesh .

Two-way coating, 6 coatings and 5 baking, multi-color synchronization, rapid color change, greatly improving production efficiency.

1)The key components such as electric motor/frequency conversion are all imported from Germany. The equipment has a high level of automation, good operation stability and guaranteed coating quality.

2)Patented automatic deviation correction, guarantees the high-speed operation and the coating quality.

3)Regardless of single-color or multi-color synchronization, the success rate of one-time painting on the machine is as high as 90%, and the quality and efficiency are both greatly improved.

4)Good oven stability, and good coating curing efficiency, greatly improving the coating surface quality.

5)High speed coating line:bottom coils maximum 100m/min, surfce coating 25-50m/min, the speed can be flexibly adjusted according to the coating needs of different products.

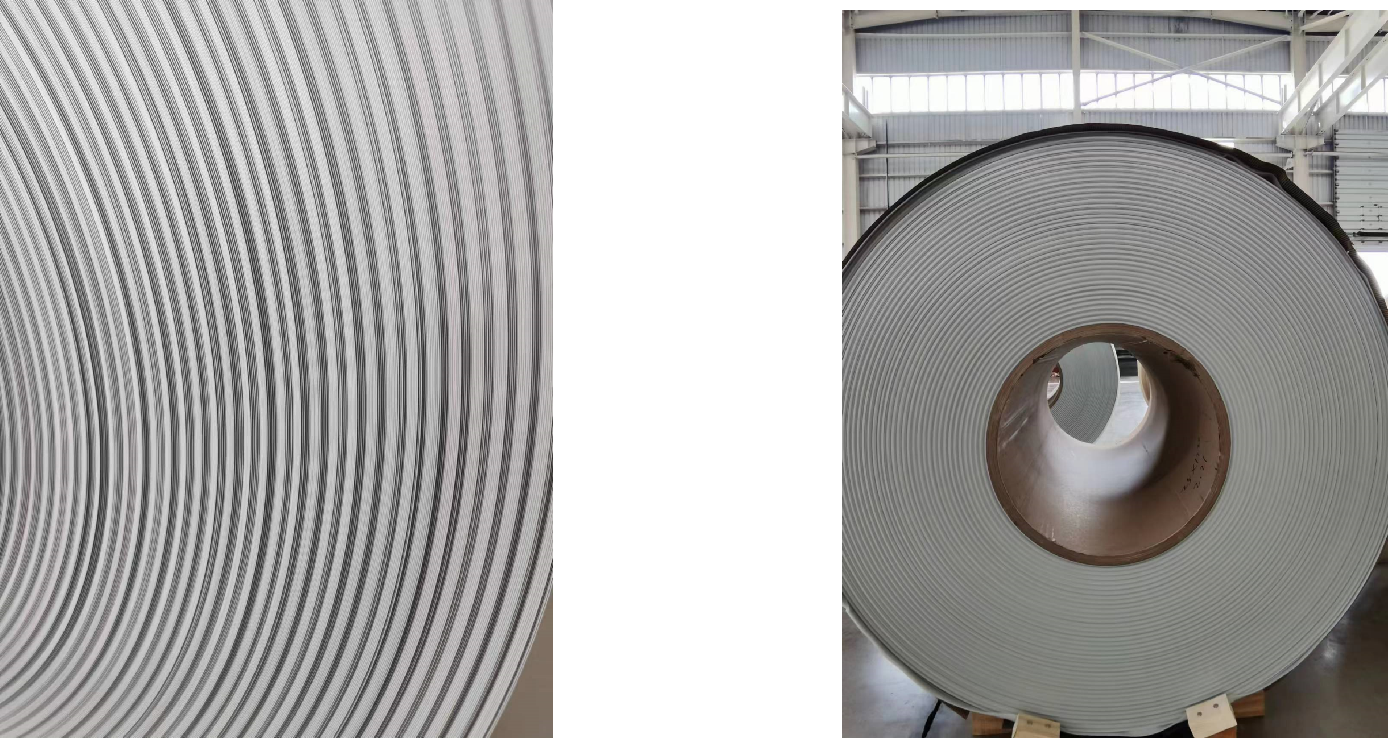

6)The patent of split-layer winding not only solves the problem of edge bumping and scraping in the production process of the product, but also solves the problem of core pulling and edge collapse in the process of transportation and storage.

Categories

News

Contact Us

Contact: ZEQI - PRC

Phone: +86 19857047922

Tel: +86 19857047922

E-mail: Sales@zeqicn.com

Add: BAIYUN ZONE, JIAOJIANG,TAIZHOU,ZHEJIANG,CHINA