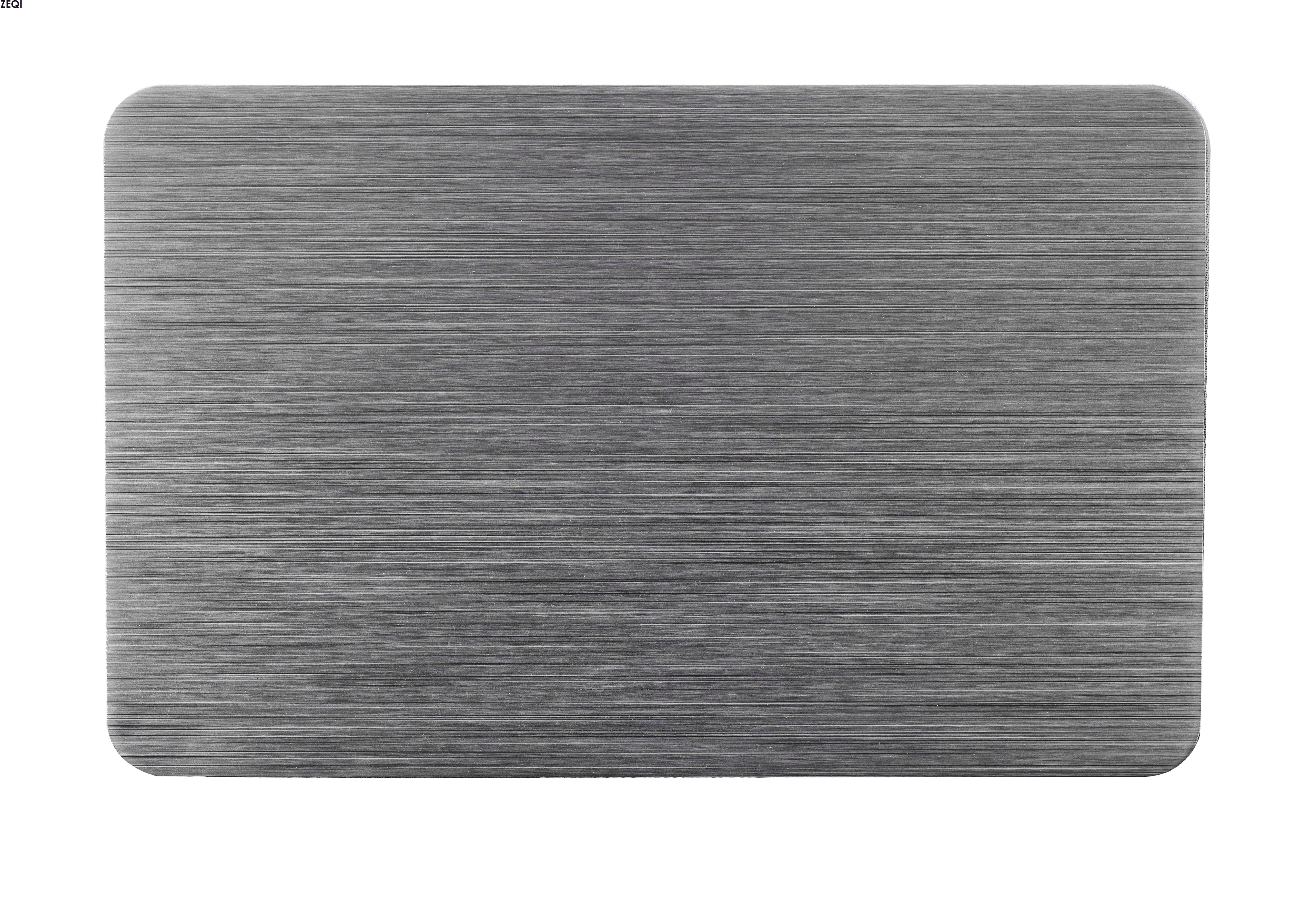

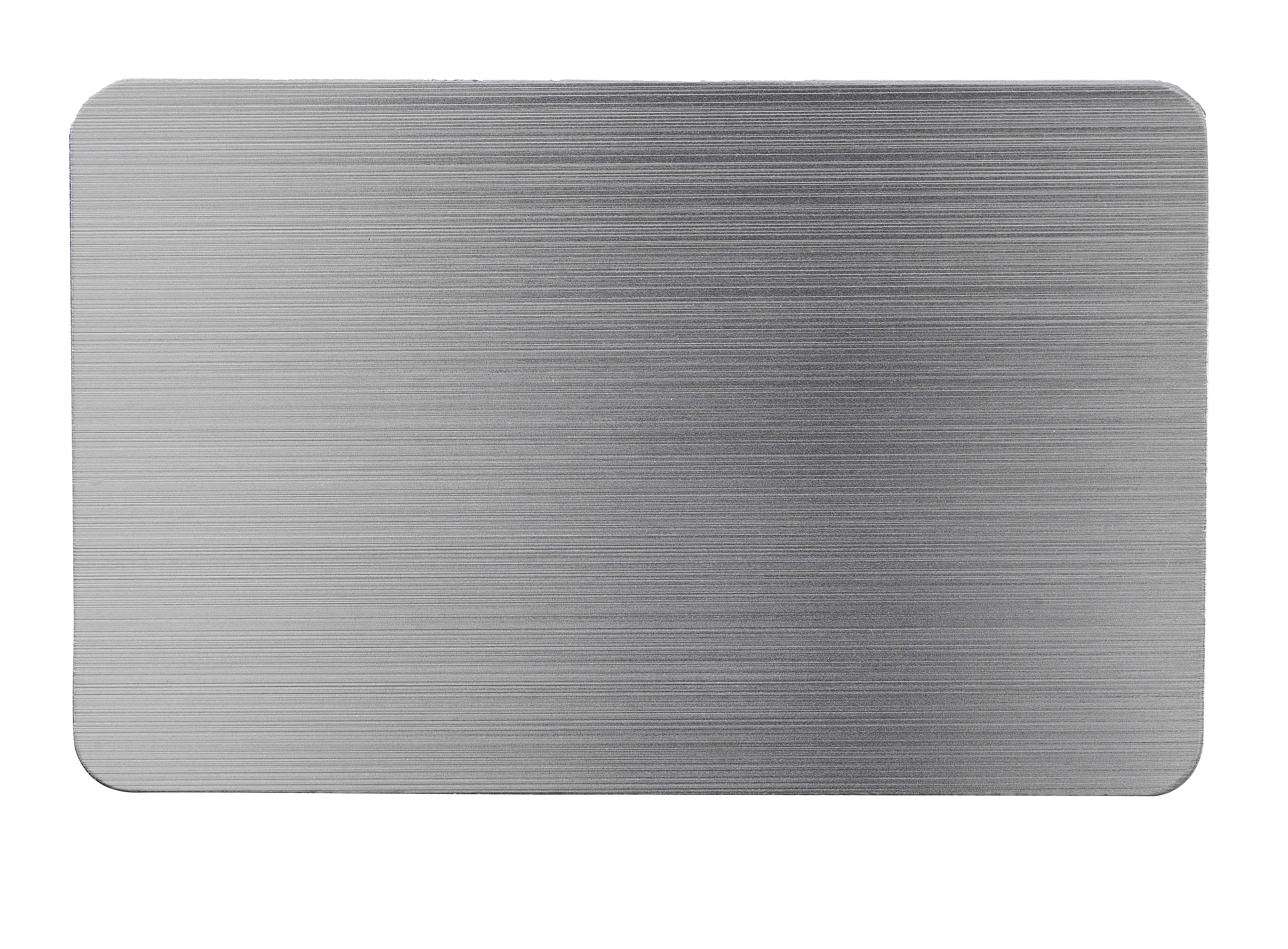

BRUSHED

Long brush aluminum

- Product ID: Long brush hair line brush aluminum

- INQUIRY

Distinct from traditional manufacturing processes that use sandpaper or nylon wheels to repeatedly scrape the aluminum surface to create brush texture, our company employs internationally advanced technology and a complete set of 1700mm Italian-imported equipment. Utilizing the steel brush roller process, we producebrushed aluminum coils with more uniform, finer grain patterns and superior pattern consistency.

The brushed surface can be directly printed, ensuring exceptional color uniformity with additional advantages include: Fingerprint-resistant surface, Fade-resistant, UV resistance, Lightweight

Excellent mechanical strength, Easy to clean, Environmentally friendly and non-toxic

Specs:

Alloy: 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc.

Thickness: 0.045~3mm

Color: Silver, gold, champagne, turquoise, bronze, copper, rose, dark gray, black, etc, as to code RAL

Texture type: Straight line drawing, short line drawing, cross line drawing, sandblasting, customized pattern

Gloss: 10-90%(EN ISO-2813:1994)

Total coating thick: Polyester/PVDF/FEVE/HDPE/ 12~27micron(EN ISO-2360:1995)

Coating hardness: 2H

Adhesion: 5B (EN ISO-2409:1994)

Impact resistance: No cracking and peeling (A.S.T.M D2794-1993)

Flexibility (T-bend): 0T- 2T

MEK resistance: 100

Certification: ISO9001:2000, CE, SGS

Coil's standard diameter: 1100mm

Inner Diameter:75mm/150mm/ 405mm/505mm

Coil's standard weight: 2000kgs

Application:

ZEQI brushed aluminum sheets are widely used in ACP,HPL,MDF, aluminum photo frames, integrated ceilings, cabinets, premium doors and windows, switch plate, signage, lighting fixtures, interior and exterior decorations, household appliances, luggage, gifts, furniture, and consumer electronics.

Categories

News

Contact Us

Contact: ZEQI - PRC

Phone: +86 19857047922

Tel: +86 19857047922

E-mail: Sales@zeqicn.com

Add: BAIYUN ZONE, JIAOJIANG,TAIZHOU,ZHEJIANG,CHINA